Root Cause Analysis: Saving on Food Safety

By Joan Martino

What do you think of when you hear the words “root cause analysis?” Many people envision a painstaking, tedious process that tries to discover the true reason a process failed. Who wants to do that?! The quick approach is to just point a finger and blame the employee. But in order to really find out the cause of a problem—and develop a method for corrective and preventive action—it is important to go beyond human error and fix the integrated procedures that contribute to the problem. Otherwise it will simply keep recurring. There are various tools and methods to determine root cause including: Failure Mode and Effects Analysis (FMEA), Pareto Analysis, Current Reality Tree and others.

One of the Simplest Tools is Using the 5-Why’s:

- Why is the metal detector rejecting product? Because there is metal in the product.

- Why is there metal in the product? Because the equipment is worn.

- Why is worn equipment causing metal to enter the product steam? … And so on.

The quick approach is to just point a finger and blame the employee

Examining a problem with metal detection “rejects” in finished goods can lead to the conclusion that worn equipment needs replacement or improved maintenance procedures, sanitation or quality inspections. The immediate corrective action for product rejected by metal detection is to “Hold” all of the product that may have been affected and, at some point, conduct a quality inspection. In most cases the suspect goods become scrap. What are the business costs associated with this?

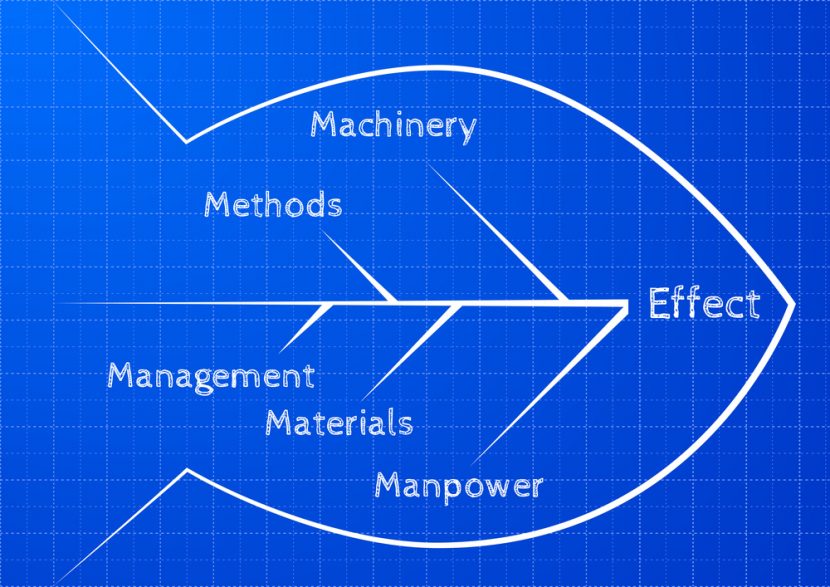

When it is important to analyze a problem more thoroughly, another great tool is the Ishikawa Diagram, (a.k.a. Fishbone, Cause and Effect). Dr. Ishikawa’s work is based on the use of process improvement teams who determine appropriate problems to work on, develop solutions and establish new procedures that refine quality, productivity and cost improvement. (Summers)

The Ishikawa Diagram provides a structured way to bring employees together and look beyond the surface to really discover why a problem disrupted the flow of business. It examines different categories and these typically include: People, Process, Equipment, Materials, Management & Environment. The questions we ask are beyond why and include what, how, when, where and so on. Now when we consider metal contamination in the product, the causal elements may be more significant and they can point the way to an integrated and long-term solution to the problem.

Once a conclusion is reached, a follow up action plan to correct the issues—with target completion dates—should be implemented, along with verification and monitoring, to close the loop. Implementing preventive actions takes it all to the next level: this step looks at processes and systems where similar failures could occur, and then applies appropriate preventive measures.

The tool can be adapted for use in both service and manufacturing areas. Not every problem requires root cause analysis. But when applied correctly, measurable cost savings can be identified in many areas, including: increased performance, improved product/service quality, less scrap, increased operation efficiency and more.

A good approach is to define specific problems where product quality, safety and legality are affected, and, where obvious errors can be corrected it is best to just fix them.

About the Author

Joan Martino is CEO of Quality Supply Chain, a company that provides simplified solutions to address regulatory compliance, supply chain initiatives and audit requirements for multiple industry sectors including food manufacturers, hospitality, retail, warehousing, packaging and equipment suppliers. She has also helped many leading US and Canadian companies integrate their systems with HACCP and GFSI requirements.

-

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

-

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

-

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

-

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

-

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

-

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants