Fight Food Fraud with These Five Labelling Tactics

By Joe Sleiman

Food fraud is a growing problem, costing the global food trade an estimated $30-$40 billion in annual losses, and it can clearly put public health at risk. While the term is typically defined as intentional deception using food for economic gain there are seven different aspects to food fraud: adulteration, tampering, overrun, theft, diversion, simulation and counterfeit.

Labelling can be an important ally in the effort to eliminate food fraud in our complex global chain. If you are a packer, grower or processor, there are five key steps you can take to reduce the risk that food fraud will someday hold your business hostage:

Step #1: Do Your Due Diligence to Fight Fraud

You want to start by critically assessing your supply chains in order to best mitigate your risks. Questions you can ask include:

Labelling can be an important ally in the effort to eliminate food fraud in our complex global chain.

1. How many years has this vendor been in business?

2. How many reputable customers does this vendor serve?

3. Do any external parties perform audits on this business?

4. What types of internal controls are in place to prevent fraud?

5. What fraud-prevention processes, people or technology are in place?

Step #2: Explore Alternative Labelling Technologies

A number of labelling technologies are available to help stop food fraud. Here are some of the best:

Pre-Printed Labels versus Real Time Print-and-Apply

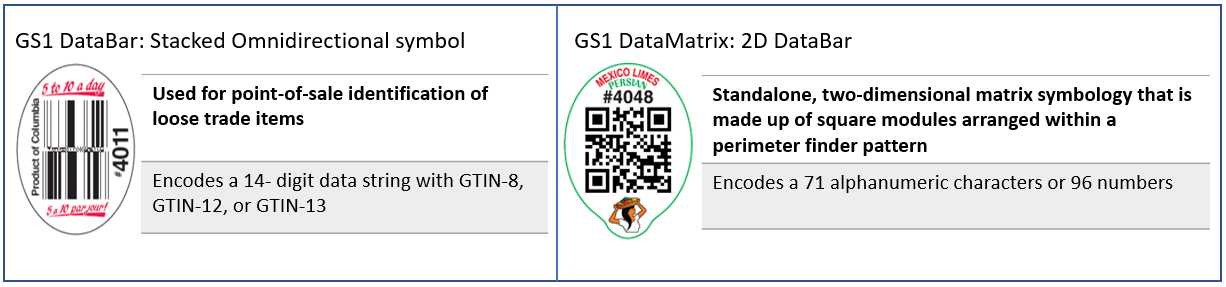

Pre-printed fruit labels include currently mandated Global Trade Item Number (GTIN) standard GS1 barcodes that include up to 14 digits for identifying a specific grower/marketer, and a Price Look Up (PLU) number. Technological advances provide the ability to print variable data in real-time, such as a DataMatrix (‘2D barcode’) which can include trace/lot code information in up to 96 digits in the same space.

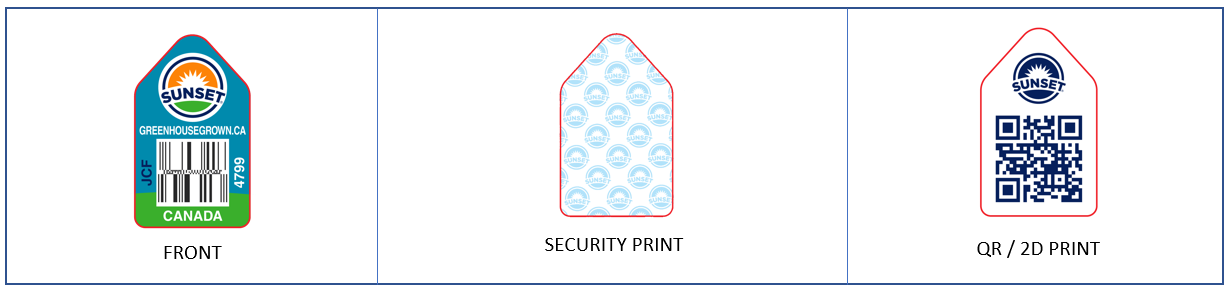

Security Print

Security Print

This technology provides verification and proof of authenticity using invisible ink watermarks under the label with reverse print technology.

Destructible Security Labels

Destructible Security Labels

These break apart when removed from fruit to prevent reapplication on another fruit.

Step #3: Apply Trace Code and Variable Data to Achieve Item-Level Traceability

Once a fruit leaves a pack house it is handled many times before it’s consumed. Fruit that has been shipped in a tray will be dumped onto a bed of “bulk” fruits making it difficult to differentiate one fruit from another unless they are properly labelled. According to the United Nations’ Food and Agriculture Organization (FAO) more than $680 billion of food is wasted each year in industrial countries and more than $310 billion in developing nations. It’s said that more than 40% of the food waste occurs at consumer and retailer levels due to product spoilage or recalls due to contaminants. Trace code can help prevent food waste as food systems can be properly outfitted to achieve forward and backward traceability. Increased traceability not only minimizes food waste but maximizes food safety to fight food fraud.

Step #4: Improve Application Rates to Prevent Unlabelled Fruits

Retailers have instituted strict quality controls on suppliers to achieve high application rates. Walmart demands a 95% label application rate, or else shipments will be returned to suppliers as rejected product. Unlabelled fruit creates an opportunity for fraudsters, allowing more leeway for mixing fruits that might be grown in substandard growing conditions.

Step #5: Understand the Impact of Transformative Labelling Technologies

Using block chain, supply chains are transformed to become more transparent, traceable and trusting with the use of shared ledgers and smart contracts. Walmart has implemented blockchain technologies to improve the traceability of mangos from six days to 2 seconds. The hyper connected IoT (Internet of Things) is a movement whereby objects are outfitted with connectivity to the internet allowing for communication amongst devices without human intervention. A compelling use case for these technologies is the cross-referencing of product data at various checkpoints to verify authenticity. Sensors such as RFID tags are becoming increasingly inexpensive and they can be used to seamlessly track products. Automation tools deliver the infrastructure to streamline processes, reduce human error and maximize efficiencies.

Food fraud is an ongoing threat to food safety, however it’s clear that advanced labelling technologies and innovations can be used to combat fraudsters and safeguard our food systems.

About the Author

Joe Sleiman, President of Ag-Tronic Control Systems Inc. and Accu-Label Inc., is an inventor turned entrepreneur that is determined to lead the produce industry into the future of Food Safety through his labelling and automations solutions. In 2001, the demand for fresh produce labelling grew so significantly that Sleiman started Accu-Label, a company that has gained a reputation as being a World Leader in Fruit Labelling Technologies, providing the most reliable equipment and Eco-Friendly paper labels.

-

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

-

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

-

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

-

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

-

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

-

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants