Research Efforts Lower the Safety Risk of Germicidal Ultraviolet Lights

By Dr. Suzanne Osborne

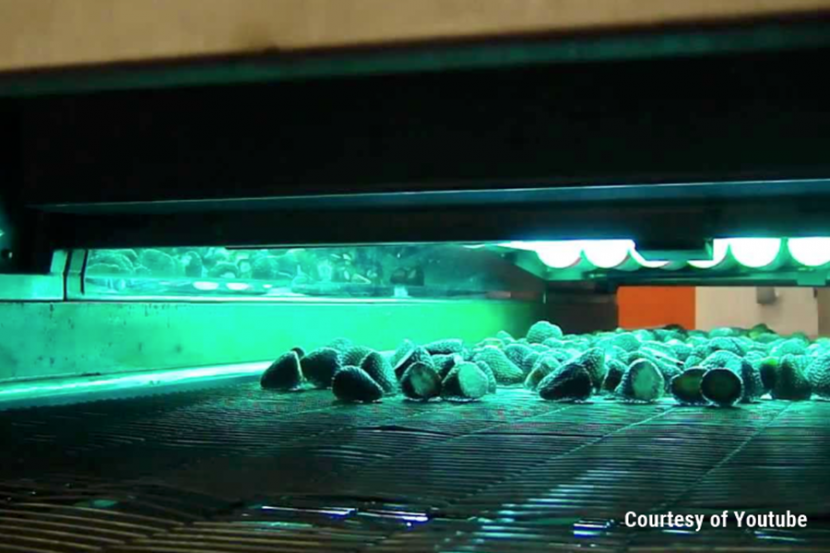

A new twist on an old technology means the food industry could soon harness greater benefits from ultraviolet (UV) light. Although it’s been used to fight foodborne illness for more than 50 years, new research is showing it can be a more practical choice for widescale use.

Light travels in waves and is classified by the distance between each wave. Any light waves that range between 10 nanometres (nm) and 400nm apart are considered UV. Humans might not be able to see UV light—it sits just outside our visible range—but it can penetrate our skin and eyes and trigger chemical reactions. Short exposure will cause pain and redness (sunburn); exposure over long periods of time can lead to skin cancer, accelerated skin aging, and cataracts.

The beauty of UV light is that it can eliminate pathogens without chemicals, by-products, or changes to the properties of the food.

UV Sterilization

Bacteria and viruses have thinner cell barriers compared to human cells. The human body is further protected by the multiple layers of cells that make up our skin. Because of this, as light waves become closer to a distance of 200nm apart, humans can withstand UV light, while pathogens are killed.

The beauty of UV light is that it can eliminate pathogens without chemicals, by-products, or changes to the properties of the food. It is relatively cost effective, efficient, and highly compatible with other treatment processes. Its main drawback for years has been its limited penetration depth, and so UV sterilization has generally been limited to decontaminating surfaces, the air, and clear liquids.

UV Lights in the Food Industry

Another challenge to using UV light has been the fact that while the US Food and Drug Administration (FDA) has approved low-pressure mercury vapor lamps to kill bacteria on specific food products, they emit light at 253.7nm and can still penetrate human tissue. As such, safety protocols and equipment must be in place to protect workers operating on or near UV light sources. This adds risk and expense to the use of UV sterilization throughout the food industry.

Recent research from the laboratory of Dr. David Brenner, overcomes this safety concern. Brenner’s research has explored the use of UV light at 222nm wavelengths (also known as “Far-UVC” light) instead of the industry standard of 253.7nm. He and his team have found that 222nm light can kill bacteria just as easily as conventional UV lamps, but without harming human skin or eyes. However, far-UV light faces the same penetration limitations as traditional germicidal lamps and is therefore best suited for the decontamination of surfaces, rather than food products themselves.

Higher Cost Savings

Far-UV Sterilray is currently the only company licenced to sell 222nm lamps. Despite higher installation costs, the extended lamp life and reduced safety limitations can translate into higher cost savings over time. Sterilray’s President, John Neister, believes 222nm lamps outperform traditional germicidal UV lights because, “Far-UV wavelengths do not pose the same risk to human exposure while they are still effective at killing pathogens. The lamps contain no mercury or electrodes, have very long lamp-life, and produce no ozone. Also, the [light] will not damage rubber or plastics.”

Using 222nm over traditional 253.7nm UV lights can significantly reduce the safety risks to line workers. UV—Far-UV—light represents an intriguing option for controlling environmental contamination of food products during processing, and it’s one that can be easily added to existing food safety best practices. As more research is done in the area, it’s inevitable that new capabilities will be developed, and new products will come to market. Food companies that can make the shift into these technologies will undoubtedly benefit.

About the Author

Dr. Suzanne Osborne‘s expertise is in the field of host-pathogen interactions and foodborne bacteria. She obtained her doctoral degree at McMaster University and worked as a Research Fellow at the Hospital for Sick Children (Toronto). She has received numerous awards for her research. Suzanne currently does freelance science writing and grant writing.

-

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

-

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

-

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

-

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

-

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

-

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants