Food Safety in Real Time

Cloud-Based Solutions for All Participants in Your Supply Chain

By Barbara Levin

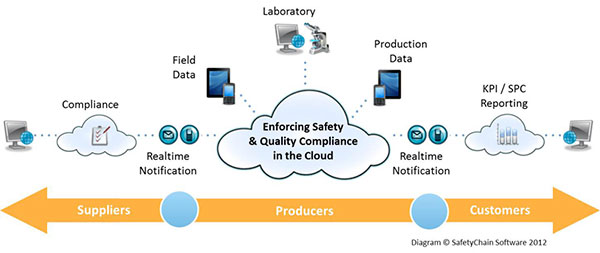

Managing safety and quality in today’s global food supply chain – inbound, during production and outbound – is a huge challenge, complicated even more by ever-evolving regulatory, non-regulatory and customer-driven requirements.

To solve this challenge, all those involved, such as suppliers, growers, manufacturers, producers, distributors, food services and retail customers are looking to the sky.

Or more to the point, to “the cloud” – to technologies that allow participants of a company’s supply chain to send and receive safety and quality test results using a computer or smart mobile application, including the electronic transmission of results from testing equipment, to secure application servers, in real time.

The technology then analyzes results to specs – also in real time, and sends information to dashboards, which can be accessed anywhere, anytime. The technology then automates COAs for results that “pass” – or issues real-time alerts when tests fail – making it easy to take immediate corrective action.

In this way, everyone in the supply chain can keep non-compliant supplies and/or raw ingredients from coming in, or out-of-spec finished goods from going out.

And because all inbound, production and outbound results are housed in a central repository in the cloud, there’s a single point of access for performance assessment and trending.

Here are some simple sample scenarios of how these technologies can support compliance along the supply chain:

Scenario 1:

- A truck of fresh meat is backing up at the manufacturer’s loading dock. The dock quality technician records temperature on a customized form on a smart tablet, such as an iPAD. The HACCP Critical Control Limit is 44° – the sample is 48°.

- Once entered, the application analyzes the HACCP data in real time. Because this sample is outside the CL, a real time notification is sent – via text or email, for example – to pre-identified people – here, perhaps, the dock manager, trucking company and the FSQA manager. The dock manager then knows immediately to put the shipment on hold before accepting, and can free up workers and equipment.

- The manager may be offsite – visiting a plant or customer – but he or she receives the alert on a mobile device. The manager can then send an immediate confirmation to the dock manager not to accept the meat – enforcing compliance, and preventing HACCP non-compliant raw material from contaminating production of finished goods.

Scenario 2:

- A field inspector is looking at lettuce in a particular location, entering pre-harvest specifications on a smart mobile device form – checking for insect infestation and other attributes. He or she sends the data, along with a picture, to the QA manager.

- The QA manager determines that the lettuce is out-of-spec, and an immediate alert is sent telling the field inspector not to harvest that field.

- Again compliance is enforced and the customer did not receive out-of-spec goods.

Scenario 3:

- A manufacturer is packaging frozen shrimp for a customer requiring 1 lb. net weight per retail bag. Information from weighing equipment is sent in real time to the cloud application.

- If the weight is within spec, the technology would automate COAs to speed throughput. However, let’s say that upon real-time analysis, the QA manager receives an alert that a particular SKU weighs in at 15 oz.

- The manager can take two immediate corrective actions: 1. Alert the packaging line to increase package weights to the minimum 1 lb., and the QA technician to place the non-complaint product on-hold; or 2. Alert production to re-label lightweight on-hold packages into an alternative product code where product weight and spec are in compliance.

The bottom line?

By having test results coming and going via the cloud, to all assigned FSQA professionals, with real time alerts automating throughput or facilitating immediate corrective actions …

- Safety and quality compliance is enforced – non-compliant goods don’t come in or go out.

- Because information is entered in any variety of formats in the cloud, it’s easy for all participants in a food supply chain to work together – without issues of one system not able to “talk” to another.

- Participants in the chain are “audit-ready” with real-time results time/date stamped with electronic signatures.

- Manual processes and errors are avoided.

- And immediate management of corrective actions works like a virtual smoke alarm, preventing bad things from happening at the earliest point possible.

About the Author

Barbara Levin in the Senior Vice President of Marketing and Customer Community for SafetyChain Software, a leading vendor of Safety Chain Management solutions. She is a frequent author and speaker on strategic use of emerging technologies to execute on business initiatives. For more information on SafetyChain Software: www.safetychain.com

To have more articles like this emailed to your inbox, become a GFSR Member today!

-

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

-

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

-

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

-

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

-

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

-

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants