What’s Next for the Bar Code

The future of bar codes in the food industry

By Nazmul Islam | Wednesday, 30 April 2014

Following the 2013 launch of the Next Generation Product Identifier (NGPI) project by The Consumer Goods Forum (TCGF) and GS1, FIA had the opportunity to speak to Mr. John Keogh, Founder and Managing Principal at supply chain advisory firm Shantalla Inc. A former Senior Vice President at GS1 Canada and adviser to GS1 Global Office, Mr. Keogh is working with Food Industry Asia from his regional base in Vietnam and recently shared his views on the future of bar codes in the food industry, and the relevance of the NGPI project to food companies in Asia.

FIA: What is the NGPI project and how will it change the bar code?

FIA: What is the NGPI project and how will it change the bar code?

John: New challenges are driving change in the consumer, retail and regulatory environments that stress the capability of today’s barcoding and item numbering systems used on all food products. I should explain that the physical bar code on a food product is actually called a “data carrier” and the human readable item number is called a “Global Trade Item Number,” or GTIN. So in essence, the project aims to determine how industry should adapt to these new challenges and determine if a more advanced data carrier and item numbering scheme is required on the product or packaging to cater to the evolving use-cases. The current bar code has been an unprecedented global success and this year, GS1 celebrates the 40th anniversary of the first bar code scan at a point-of-sale in the USA. It has served the food industry very well by driving efficiencies estimated to be in the hundreds of billions of dollars (USD). In fact, the bar code is one of the most trusted tools used across industries today, with an estimated 5 billion bar code scans every day.

FIA: What are these new challenges and why is it important for FIA members?

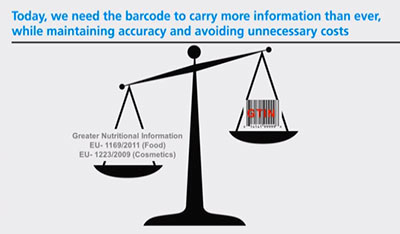

John: We first have to acknowledge the rapid pace of change and the evolution of the retail environment. This is being powered by consumer demands for information at one end of the spectrum and increasing regulatory requirements at the other end. Some of the new food safety requirements are beyond current standards and capabilities in the supply chain. They require a collaborative effort from key stakeholders to research and prepare for a new digital world enabled by global standards. A digital world where data attributes have greater accuracy and transparency than today, both of which are key enablers of consumer trust.

With the rise of social media, we know that industry needs to respond more effectively to consumer demand for instant information. This will become increasingly critical if we are to protect consumer trust and preserve brand value. For product safety reasons alone, additional data attributes on the food product or packaging will facilitate a step change with greater effectiveness in food traceability, recall and brand protection. These are just a few of the use-cases envisaged by the NGPI. It is very important for FIA members from both manufacturing and retail to be engaged, to understand the scope of the project and its relevance to them, and in turn to provide a regional focal point in the global dialogue.

FIA: What additional data attributes have been identified?

FIA: What additional data attributes have been identified?

John: The NGPI core team has identified about 50 use-cases that have five common data attributes that need to be added to the GTIN for future business needs. They include a Product Variant Number or PVN that could be used to identify minor variations of the same product (promotional images on packaging, minor changes to ingredients, etc.) rather than assigning a new product identifier for each one. The attributes also include the brand URL, lot #, expiry date and a product serial number. Taken together, the GTIN plus these five attributes will enable many of the defined use-cases and lay the foundation for the next 40 years. The use-cases will facilitate enhancements in consumer health and safety that may eliminate the need for governments to regulate further.

FIA: Have other segments or industries experienced similar changes?

John: The NGPI project’s core team will build on the learnings and experiences from industry segments such as fresh produce who are applying a data carrier called a GS1 DataBar that has additional data attributes aimed at efficiencies and reduction of food waste. The GS1 DataBar is a small thumbnail-sized bar code you may see on an individual apple or orange that can enable traceability to the brand owner or produce packer and could include the harvest date or use by date etc. Similarly, the pharmaceutical industry has very specific business and regulatory requirements. These requirements specify which data attributes need to be carried on the product or packaging. Once the data requirements have been defined, the most appropriate data carrier can then be selected.

In the pharmaceutical industry, a data carrier called a GS1 DataMatrix allows for more data attributes to be encoded into the data carrier such as GTIN, batch, expiry and serial number. While the GS1 DataBar can be used at point-of-sale, GS1 DataMatrix was not originally intended for point-of-sale purposes so further research and eventual pilots need to occur to determine a cohesive industry strategy and implementation roadmap. Other data carriers such as the GS1 QR Code are part of the evaluation process.

FIA: Who is involved in the project?

FIA: Who is involved in the project?

John: This is truly a global project being run jointly by TCGF and GS1. There is a lead retailer and manufacturing organization assigned in each market and they must reach out to appropriate entities to build community and scale. For the USA market, the Grocery Manufacturers Association (GMA) and the Food Marketing Institute (FMI) will work with GS1 US and other stakeholders. In Europe AIM, Food-Drink Europe, EuroCommerce and GS1 Europe will be jointly handling this project. For the Asian market, FIA will take the lead and I have been assigned by FIA to facilitate this work and ensure alignment with GS1 across Asia.

FIA: What is the NGPI story so far and what’s next?

John: As mentioned, the NGPI core team has identified five additional data attributes that could address the identified use-cases if they were to be included on the product or packaging in machine and human-readable formats. But a lot of work still has to be done to examine each data attribute and determine if a GS1 standard already exists and, if so, how will the attribute be used and what is the impact across the entire value chain. Additionally, it needs to be determined what candidate categories can/should it be applied to.

In the long term, industry should build the capability to utilize advanced GS1 data carriers at the consumer package level for the point of sale and consumers. Companies can choose to keep their current bar coding system in place and a sunset date will not be set. However, the new attributes offer significant value-added capability with improved efficiencies and the ability to build trust through enhanced transparency. This should make it very compelling for both retailers and manufacturers to join in and accelerate national, regional and global adoption.

In the short term, I will represent FIA on monthly calls with the global and regional liaison teams and also on bi-weekly calls with GS1 on their NGPI standards development committee. The core NGPI project team is on schedule to deliver their final recommendations and a plan for industry engagement before the summer break in June. The regional preparation work will continue through the FIA Committees who will draft an initial mandate for a new FIA Supply Chain Forum with NGPI as the first project. Once approved by the FIA Council, we will initiate stakeholder engagement.

FIA: Final words, John?

John: Stay close and keep tuned, this is going to be very important and engaging work and I look forward to receiving your input and guidance.

About the Author

Nazmul Islam is the Membership & Communications Manager for Food Industry Asia (FIA), which is a leading voice of the food industry in Asia, and was formed in 2010 to enable major food companies to address non-competitive issues and share best practices.

To have more articles like this emailed to your inbox, become a GFSR Member today!

-

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

FeaturedRisk management

The Cost of a Breach: What a Cyberattack Could Mean for Food Safety Recalls

-

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

FeaturedRisk management

Securing the Food Chain: How ISO/IEC 27001 Strengthens Cybersecurity

-

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

FeaturedRisk management

Revolutionizing Food Safety Training: Breaking Out of the “Check-the-Box” Mentality

-

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

GFSI Standards

GFSI 2025: Building Trust, Tech-Forward Solutions, and Global Unity in Food Safety

-

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

FeaturedFood Safety

Integrated Pest Management: Strategies to Protect Your Brand’s Reputation

-

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants

FeaturedFood Safety Culture & Training

No Open Door Policy: Challenges That Impact Pest Control in Food Processing Plants